Polymers in Cryogenic Applications

When most people think about materials, they usually wonder how high a temperature a substance can withstand. However, in cryogenic settings—where substances like liquid nitrogen, oxygen, carbon dioxide, and liquefied natural gas are involved—it's crucial to understand how materials behave under extremely cold conditions. In these environments, polymer fasteners provide an excellent solution, especially in temperatures below -150°C, while maintaining low thermal conductivity. As cryogenic technology continues to expand, this field of engineering is becoming increasingly relevant across various industries, including: • Supercomputing • Pharmaceuticals and biotechnology • Superconductors • Magnetic technologiesAdvantages of Polymers in Cold Environments

Polymers offer several benefits in cryogenic applications: • Low thermal conductivity reduces heat transfer, keeping systems efficient. • Excellent electrical insulation ensures safety and reliability. • Superior sealing performance helps maintain system integrity. • Self-lubricating properties reduce wear and tear without external lubricants. • Mechanical stability ensures consistent performance over time. While polymers perform admirably in cold environments, they do come with certain trade-offs. At cryogenic temperatures, they tend to become stronger, stiffer, and harder, which can reduce their toughness and make them more brittle. Despite this, most polymers recover their original properties once warmed back to room temperature.Fluoropolymers: The Cryogenic Champions

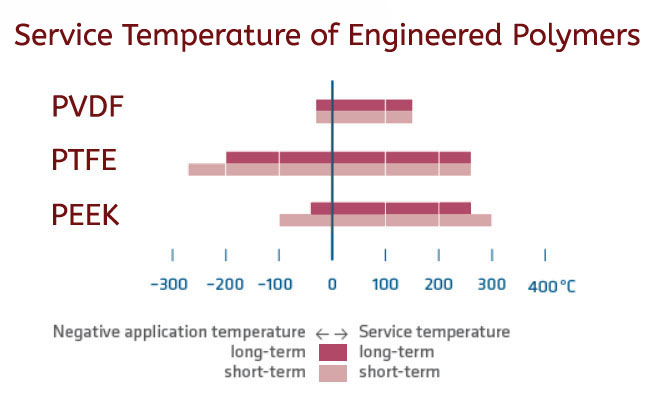

Among polymers, fluoropolymers stand out for their exceptional performance in cryogenic conditions. Examples include PVDF, PTFE, and PFA. Although they lose some flexibility at low temperatures, fluoropolymers retain their lubricity, abrasion resistance, and mechanical strength. Studies have shown that PTFE is particularly well-suited for cryogenic use. It can function effectively down to -328°F (-200°C) without becoming brittle and remains flexible down to nearly -100°F below that. Other fluoropolymers may perform well in extreme cold, but they often fail to match the versatility and durability of PTFE.

Filled vs. Unfilled Polymers

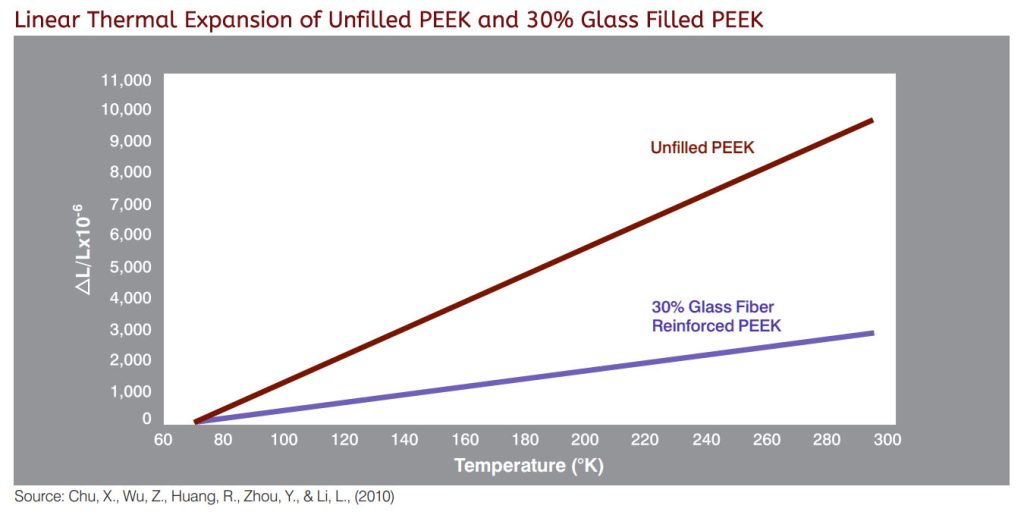

It’s worth noting that reinforcing polymers with fibers like glass or carbon can make them more brittle at cryogenic temperatures. For applications involving significant temperature fluctuations, it’s best practice to choose a filled polymer grade, which helps stabilize expansion. For instance, unfilled PEEK expands by about 1%, whereas 30% glass-reinforced PEEK expands only 0.3%.

The Ductile/Brittle Transition

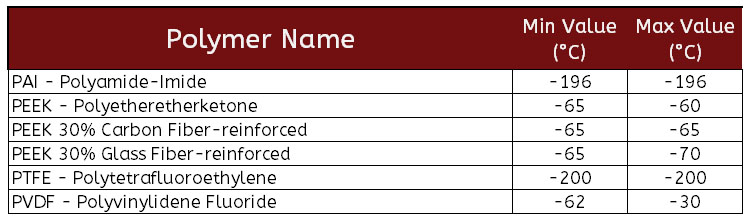

Understanding the ductile-to-brittle transition temperature is critical for selecting the right polymer for cryogenic applications. Below certain temperatures, polymers shift from being ductile to brittle, impacting their performance. This chart illustrates the transition points for different materials. In conclusion, while polymers present challenges at cryogenic temperatures, their unique properties make them indispensable in many advanced applications. By carefully selecting the appropriate type and grade, engineers can optimize performance and reliability in extreme cold environments.

In conclusion, while polymers present challenges at cryogenic temperatures, their unique properties make them indispensable in many advanced applications. By carefully selecting the appropriate type and grade, engineers can optimize performance and reliability in extreme cold environments.Insulated Composite Insulation Air Duct

Insulated Composite Insulation Air Duct,Fabric Air Duct Colling Systems,Fabric Duct,Fabric Ductwork

Jiangsu Buna Technology Development Co. , Ltd. , https://www.bunaduct.com