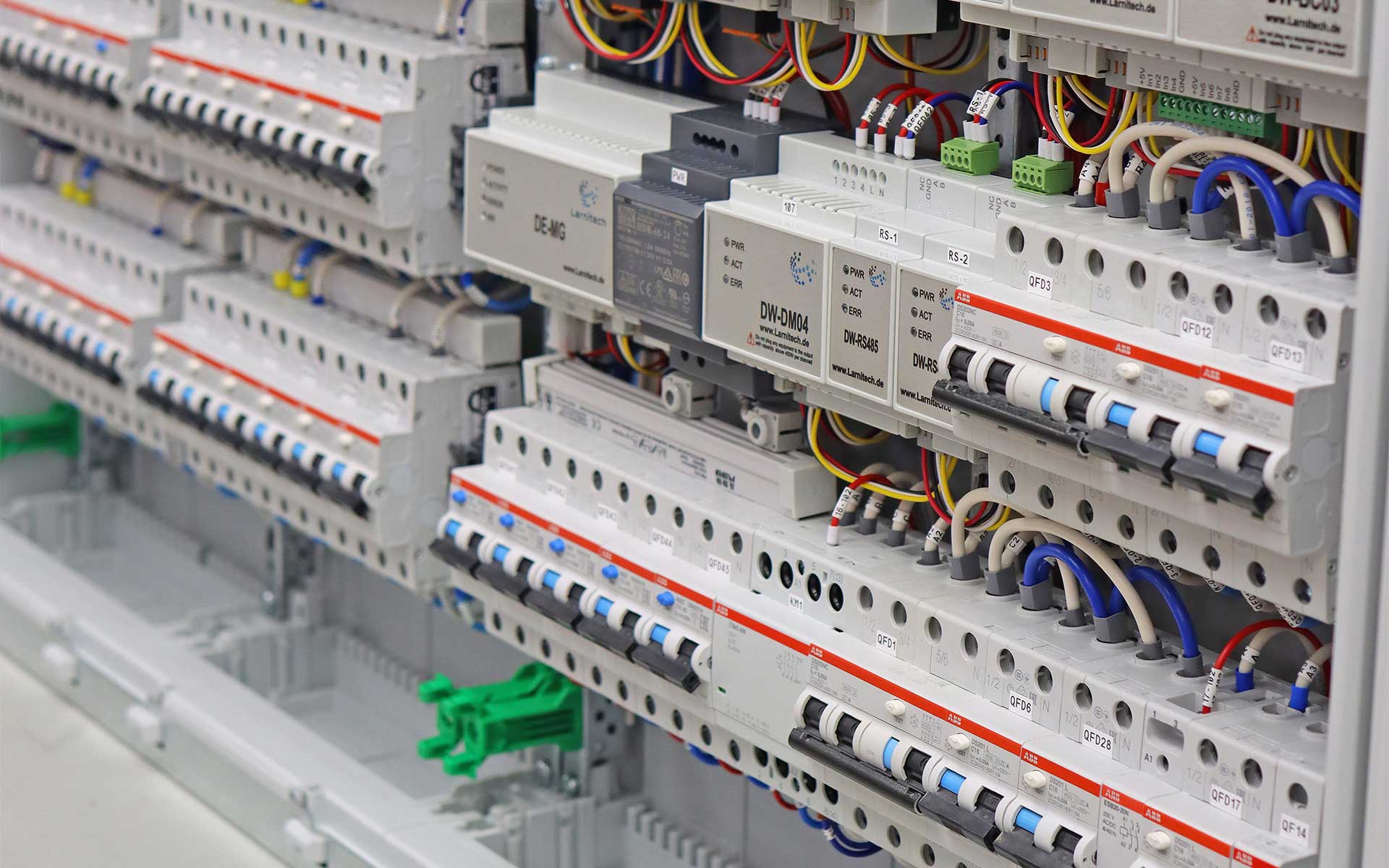

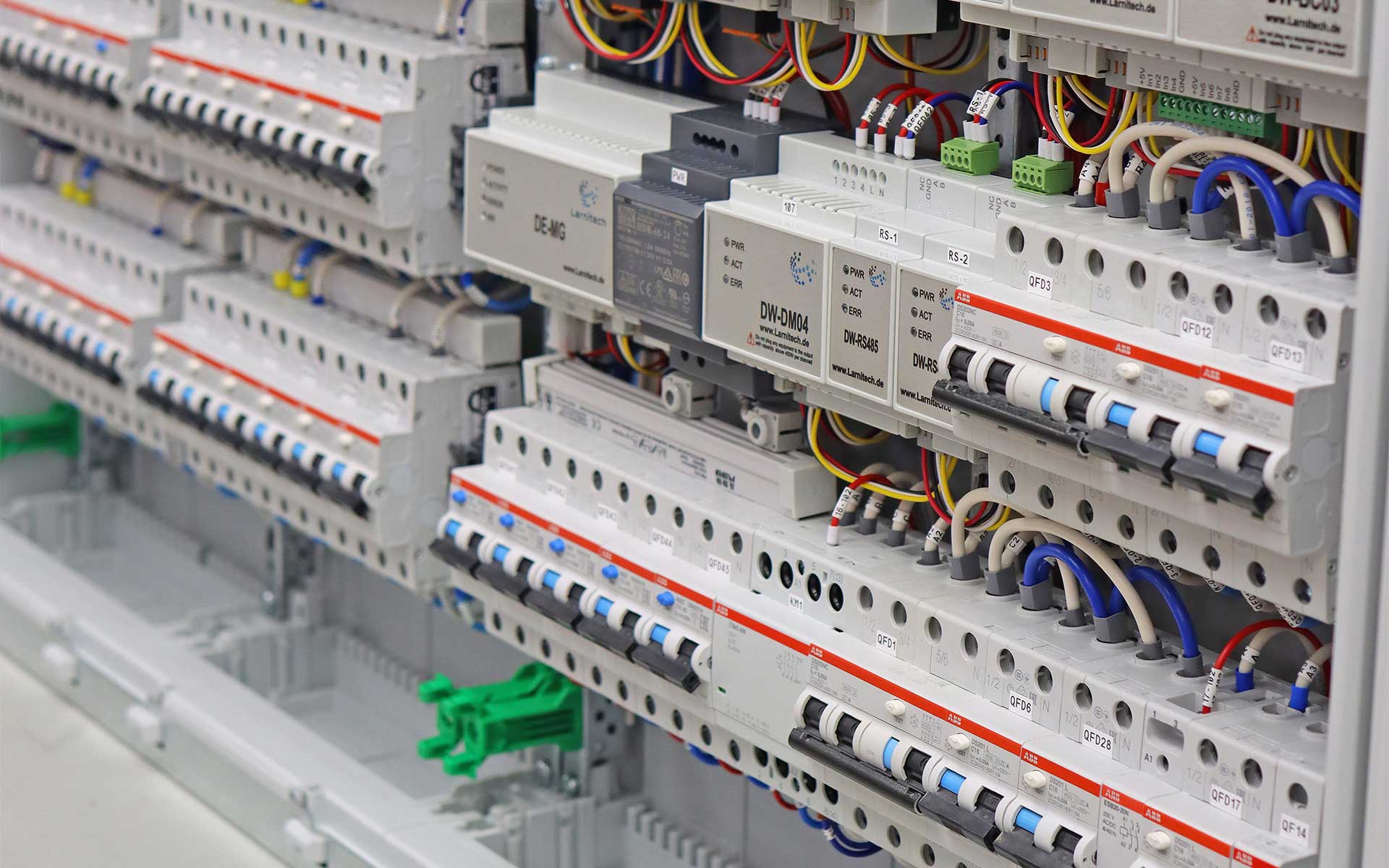

A custom DIN rail assembly provides a standardized, modular, and space-saving solution for mounting and organizing electrical components like circuit breakers, terminal blocks, and other industrial devices. These assemblies simplify installation, maintenance, and scalability of electrical systems and are widely used in industrial control systems, automation, and electrical distribution due to their simplicity and efficiency.

At Peerless Electronics, we offer custom-assembled DIN rails as part of our Value-Added services, which are complimentary to Peerless customers. Our latest post delves into this valuable service, offering more insights into how it works, the various customization options, common use cases, and how it can help organizations save both time and money.

What is DIN Rail Mounting?

DIN rails are metal rails, typically made of steel, that securely assemble and house components in equipment racks and control cabinets, optimizing space while providing efficient electrical connections. DIN rail mounts come in various sizes, with the most common being the top hat DIN rail measuring 35 mm wide. The term "DIN" originates from the German Institute for Standardization, translated as "Deutsches Institut für Normung," where the rail-mounting system was first established in the late 1920s.

Customizing DIN Rail Assemblies

Custom-assembled DIN rails offer a seamless solution for organizing electrical devices safely and securely within an application, enabling easy installation and removal of electrical devices without additional hardware. However, DIN rail mounts often need customization to meet specific application needs. Customizing DIN rail assemblies involves tailoring specific aspects, such as the rail type, material, length, device positioning, and enclosure protection, to adapt to specific industrial and electrical setups. Tailoring these aspects of the system, as detailed below, enhances overall reliability, safety, and ease of maintenance.

Profile Rail Designs

While the top hat rail is the most common, some electrical and industrial applications may require alternative DIN rail types, such as miniature rails or G-type rails. For instance, miniature rails are narrower (15mm) and ideal for compact installations. G-type rails, on the other hand, are wider and deeper than the top hat and better suited for heavier components and older installations. Customizing DIN rail systems with specific rail designs to support the components' size and weight improves the system's reliability.

Din Rail Mount Enclosures Customization

DIN rail mount enclosures are protective housings or enclosures used to safeguard DIN rail systems’ mounted electrical components. These enclosures are crucial in environments where dust, moisture, debris, or other factors can threaten sensitive electrical devices mounted on the rail system. For example, heat-sensitive components may require additional thermal management within the enclosure, and custom ventilation slots, fans, or heat sinks can be integrated into the enclosure design to prevent overheating.

Custom DIN Rail Styles

DIN rail styles encompass variations in size, shape, material, and design of DIN rails, and customization provides tailored solutions to fit the exact requirements of an application. This is particularly important for unique setups in industrial, commercial, or specialized environments. For instance, an application may require a short DIN rail assembly or a special DIN rail clip design to ensure installation ease and component organization efficiency. Customizations can include specific DIN rail material types, sizes, and lengths, as well as other features like perforations, snap-on mechanisms, or pre-drilled holes.

Applications of Custom DIN Rail Assemblies

Custom-assembled DIN rails play a vital role in enhancing performance across a wide range of industrial settings, offering flexibility and protection for electrical component organization within applications. Here are some specific examples of how custom DIN rail assemblies can improve the reliability, safety, and scalability of industrial electrical and control systems.

DIN Rail Assemblies for Electrical Switchgear

DIN Rail assemblies for electrical switchgear are crucial for managing and organizing electrical components in power distribution systems. They provide a structured and efficient method for organizing devices like circuit breakers, relays, transformers, and communication equipment inside the switchgear cabinets. For instance, switchgear in heavy industrial settings often operates in high-temperature environments. Thus, a custom DIN rail assembly design may incorporate thermal dissipation properties for better durability and long-term functionality.

DIN Rail Assemblies for Industrial Process Control and Monitoring

Customized DIN rail assemblies are often essential in industrial environments using systems for process control and monitoring, such as a water treatment plant. In this environment, high levels of moisture and chemicals are prevalent, so a custom DIN rail assembly may include stainless steel or coated aluminum DIN rail mounts to prevent rusting. These custom DIN rail assemblies may also require NEMA-rated enclosure boxes to protect sensitive electronic components from water exposure and damage.

DIN Rail Assemblies for Factory Automation

Custom DIN rail assemblies are integral for managing control components within factory automation systems, including sensors, relays, and motor controllers. To ensure these sensitive components remain secure in factory environments, DIN rail customizations can include heavy-duty DIN rail mounts to combat high vibrations and integrated ventilation to prevent components from overheating.

Overall, custom DIN rail assemblies are instrumental in keeping electrical components secure, protected, organized, and accessible within demanding industrial environments. Optimizing the DIN rail mounting and assembly features to fit the unique demands of the environment ensures better reliability, safety, and scalability of electrical control and other systems.

The Advantages of Custom DIN Rail Assemblies

We’ve already discussed many advantages of customized DIN rail assemblies, including ensuring better long-term performance and adaptability of electrical systems. Let’s summarize the benefits of customizing the design, layout, and materials of DIN rails to address electrical and control system challenges.

- Reduces unproductive labor (no cutting or tooling required)

- Reduces installation time

- Streamlines maintenance and troubleshooting

- Provides a tailored fit for better space optimization

- Integrates safety features for improved protection

- Provides scalability for system upgrades and expansions

- Ensures regulatory compliance by meeting industry standards

- Incorporates better durability for harsh environments

- Reduces long-term costs with precise design, supporting safety, durability, and longevity

Peerless Electronics Superior Custom DIN Rail Assembly

Peerless Electronics is an authorized stocking distributor for the world’s leading manufacturers and suppliers within the military, aerospace, industrial, transportation, and medical sectors. While supplying quality electrical parts is part of what we do to support clients worldwide, we go beyond that by offering top-notch value-added services. These services, including customized DIN rail clip assembly, allow customers to transform their orders into high-quality, customized experiences.

The Peerless Value-Added (VA) Experience, which also includes custom-tailored technical support, offers quick turnaround times to save time, maintain workflow, lower costs, and support efficient workforce allocation. At Peerless, customization, quality, and service are paramount to doing business the right way—by putting customers first.

FAQs

What components can be included in a custom DIN rail assembly?

The specific components will depend on your application’s requirements, whether for industrial automation, power distribution, or specialized monitoring systems. Peerless Electronics carries thousands of components that can be integrated into a custom DIN rail assembly—some of our key manufacturers include Entrelec, Carlo Gavazzi, CBI, and Altech.

What types of DIN rails are available for custom assemblies?

We can customize any DIN rails purchased on the Peerless Electronics website as part of our Value Added support services.

Can DIN rails be cut to custom lengths?

Yes, DIN rail mounts can be cut to your specified length, ensuring a custom-tailored fit.

Pneumatic valve is a kind of valve controlled by air pressure, which is widely used in industrial automation control system. Its main applications include the following aspects:

1. Fluid control: pneumatic valve can be used to control the flow and direction of liquid or gas, such as controlling the flow in the pipeline, exhaust gas emission, etc.

2. Pressure control: pneumatic valve can be used to control the pressure of fluid, such as controlling the pressure of compressed air, regulating the pressure in the hydraulic system, etc.

3. Temperature control: pneumatic valve can be used to control the temperature of fluid, such as the temperature of heating or cooling system.

4. Automatic control: pneumatic valve can be linked with sensors, PLC and other equipment to realize automatic control, such as automatic production lines, robots, etc.

5. Safety control: pneumatic valve can be used for safety control, such as controlling emergency stop, preventing overload, etc.

In general, pneumatic valve plays an important role in industrial automation control system, which can improve production efficiency, reduce costs, and ensure safety.

Pneumatic Valve,Pneumatic Valve Types,Pneumatic Control Valve,Pneumatic Actuator Valve

WUXI KVC-VALVE , https://www.wxkaiweixi.com